Since as early as the 1950’s, numerous metal part applications have been converted to plastic, beginning with the automotive and aerospace industries. More recently, the medical and oil & gas industries have also utilized metal to plastic conversions, yet a great deal more conversion opportunities remain unevaluated. Manufacturing designers and engineers may dismiss plastics simply because their part has historically been made from metal. Consequently, many manufacturers are missing the cost benefits and weight reduction, among other benefits, produced by plastic.

Why Does It Matter?

Metals offer a wide range of capabilities designers and engineers are historically accustomed to, but plastic capabilities are not as widely recognized and more often than not, they’re misunderstood. Fortunately, as material testing methods have continued to progress, so have manufacturers’ material understanding of the vast range of plastic applications.

With manufacturers’ improved material testing, now designers and engineers can better predict how plastics will perform under the same stresses traditionally experienced when testing metals. With an understanding of the stresses parts will undergo in their application environments, designers and engineers can utilize material selection tools to identify optimal metal to plastic conversion candidates.

Advantages of Metal to Plastic Conversion?

- Increased design options

- Better material flexibility

- Reduced cost

- Weight reduction

- Corrosion resistance

- Equal or greater material strength

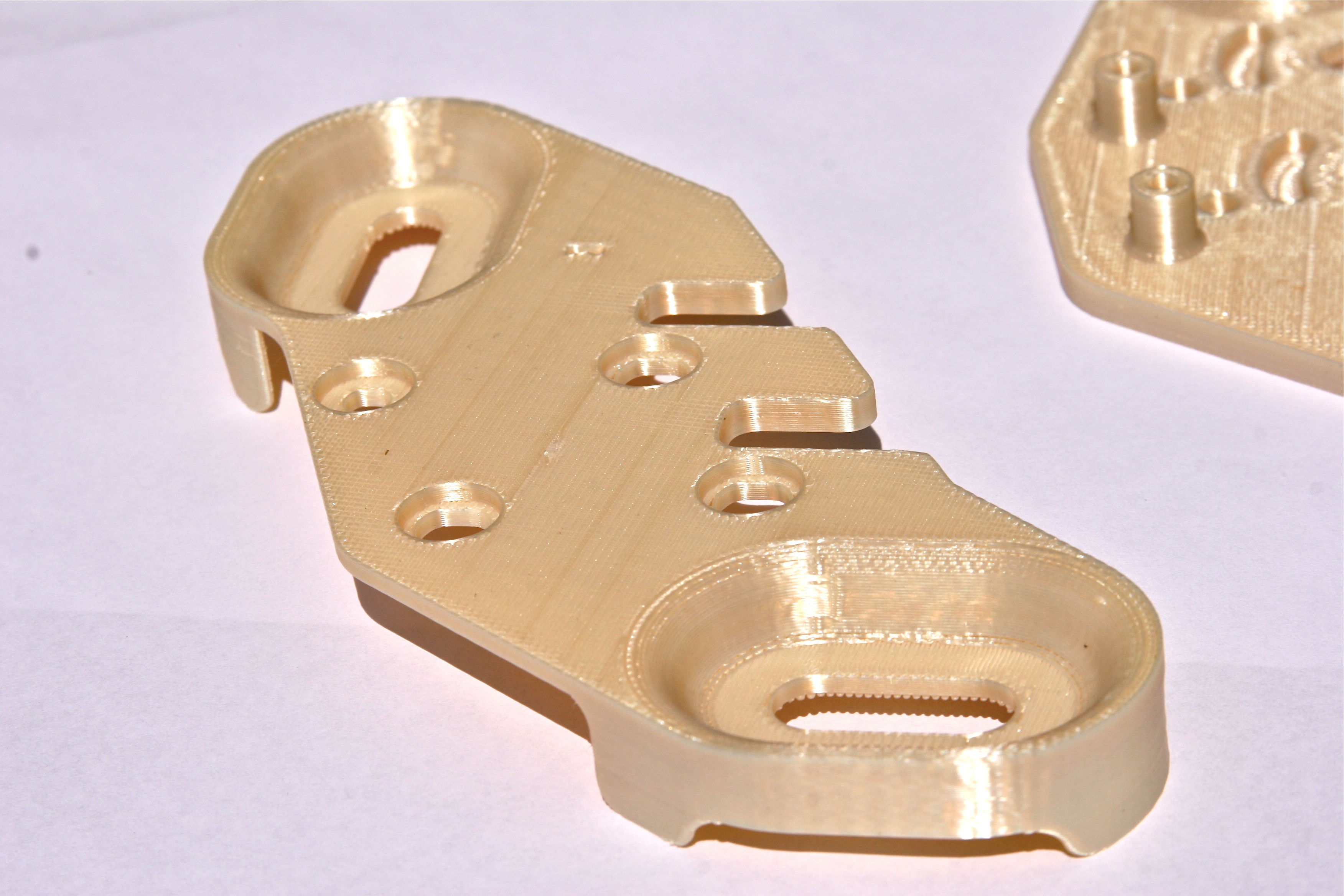

Unlike metals, plastics can more easily be formulated into complex and/or smaller shapes versus metal. Whether it be injection molding, plastic machining, or a combination of the two, plastics afford manufacturing designers and engineers to produce complex, thin-walled parts with uniform wall dimensions and tight hole tolerances.

Cost reduction due to conversion to plastics components is arguably the most powerful manufacturing advantage plastics provides. Most notably, due to the fact that plastics are so much lighter than their metal counterparts, considerable costs can be avoided on shipping and distribution, including both raw materials and finished parts. As a result, metal to plastic conversion can be a major step towards making US manufacturing companies more competitive with low-cost manufacturing countries.

Plastics provide tremendous material flexibility, to the point where vendors can compound a variety of plastic materials with particular fillers and reinforcements to optimize the material’s structural integrity, electrical properties, and specific gravity, among other characteristics. With the availability of advanced engineering plastics like PEEK, Ultem®, and Torlon®, manufacturing designers can determine which application characteristics are most important and vendors will customize the material to meet the requirements.

While manufacturers benefit from making the switch, identifying the optimal design candidates for metal to plastic conversion requires informed analysis and is not necessarily a quick determination. Material conversion analysis must take into account the end-use application, designing for manufacturability, and economic feasibility, to ensure manufacturers are accurately evaluating the real-world environment that will affect the part.

The Application Development Team at Roncelli Plastics serves as a valuable resource for manufacturing designers and engineers seeking to identify metal to plastic conversion opportunities. Our experienced team conducts thorough evaluations to analyze the application’s environmental conditions in order to provide recommendations for improving manufacturability.

For more information on Roncelli Plastics’ application development support, request a consultation today.

{{cta(‘247cb1b8-f62a-4d8c-a355-908f23261361’)}}